The quality of white PCD sample was found to be very high by Raman Spectroscopy. It has been found that under atmospheric conditions, the CVD diamond sample could sustain up to 700°C furnace temperature, but 750°C was not tolerable for the diamond material to resist oxidation. As per available literature [38], the procedure to study the thermal stability is to heat the diamond sample in an environment controlled furnace, but such procedure does not pinpoint the oxidation temperature of diamond material. In order to know the exact oxidation temperature of the CVD diamond prepared by DT1800 reactor, it was decided to conduct TGA-DSC experiments.

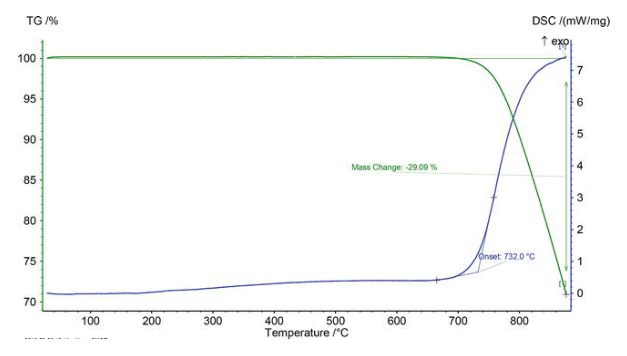

Figure 3 shows the TGA curve for white PCD sample when heated from room temperature at constant heating rate of 10 K/min in air with alumina crucible up to 900°C. There was no change in weight until 700°C temperature was crossed, after which there was continuous drop in weight, losing 29.09% of the initial value. The corresponding DSC curve shows that the exact onset temperature for oxidation reaction is 732°C, after drawing tangents. The weight loss can be attributed to the loss of carbon from diamond as gaseous by product of oxidation reaction. So, further to study the behaviour of CVD grown defects in PCD samples, they were heated in an air furnace at 600°C for 1 h. Such TGA-DSC curves confirm that annealed PCD samples do not undergo degradation on annealing and are good for studying the effect of heating on their internal defects.

Figure 3.

TGA and DSC curves for heating CVD diamond in air.

3.2 Spectroscopy: FTIR, PL and Raman—PCD defects and annealing effects

3.2.1 FTIR studies

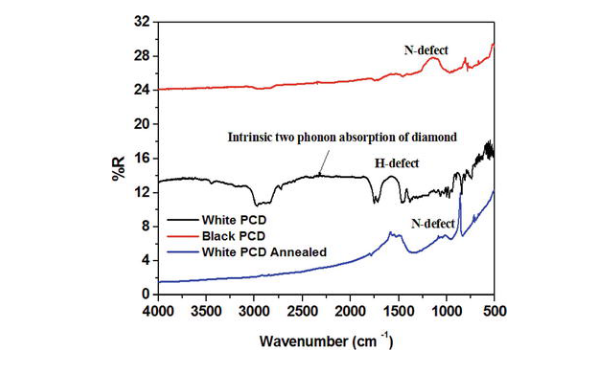

The FTIR reflectance spectra of as grown PCD samples, white PCD and black PCD, together with white PCD sample after being annealed at 600°C for 1 h are presented in Figure 4. The spectra reveal the presence of a broad absorption peak in the range 1745–2840 cm−1 in white PCD sample which may be attributed to the characteristic two phonon absorption of diamond [122, 123] and it is seen to be almost absent in black PCD sample. However, this peak disappears completely in annealed white PCD sample with simultaneous appearance of a new peak at 1090 cm−1. Interestingly, the peak at 1090 cm−1 is observed to be more intense in as prepared black PCD sample. This peak marks the presence of N-defects in diamond lattice [123]. Thus, it can be stated that the as grown white PCD sample contains less nitrogen defects as compared to black PCD and is of better quality in terms of non-diamond inclusions. As a result characteristic carbon-carbon bond absorption vibrational modes are more distinct in white PCD as compared to black PCD, which has many internal planar and volume defects as already observed in Figure 2. But, annealing at 600°C results in the growth of atomic defect centres in white PCD sample. As the nitrogen impurity centres grow at the expense of carbon replacement in the lattice, intrinsic absorption band due to diamond is weakened while the vibrational band due to N-defects intensifies.

Figure 4.

FTIR spectra of different PCD samples.

In addition, a third distinct peak is noticed at around 1490 cm−1 in both as grown white PCD and annealed sample which may be assigned to absorption due to H-centres trapped in the lattice [124]. In black PCD sample this peak is seen to be extremely weak in nature. This may be explained on the basis of the processing condition of the two samples. White PCD was grown with 1% methane and 99% hydrogen whereas black PCD was grown with 3% methane and 97% hydrogen. Thus use of more hydrogen precursor during the CVD process may have resulted in trapping of H-centres in the lattice of white PCD. For further confirmation of the presence of impurity centres, photoluminescence study of these samples was performed.

Whatsapp/wechat

Whatsapp/wechat