We offer top quality of domestic and E6 brand of PCD blanks for cutting tools widely used for woodworking, plastic, CNC metal working industry etc.

There is good stock for E6 brand of PCD blanks in our wearhouse, which quality is 20-30% higher than domestic type, but price is around 15% higher than domestic type.

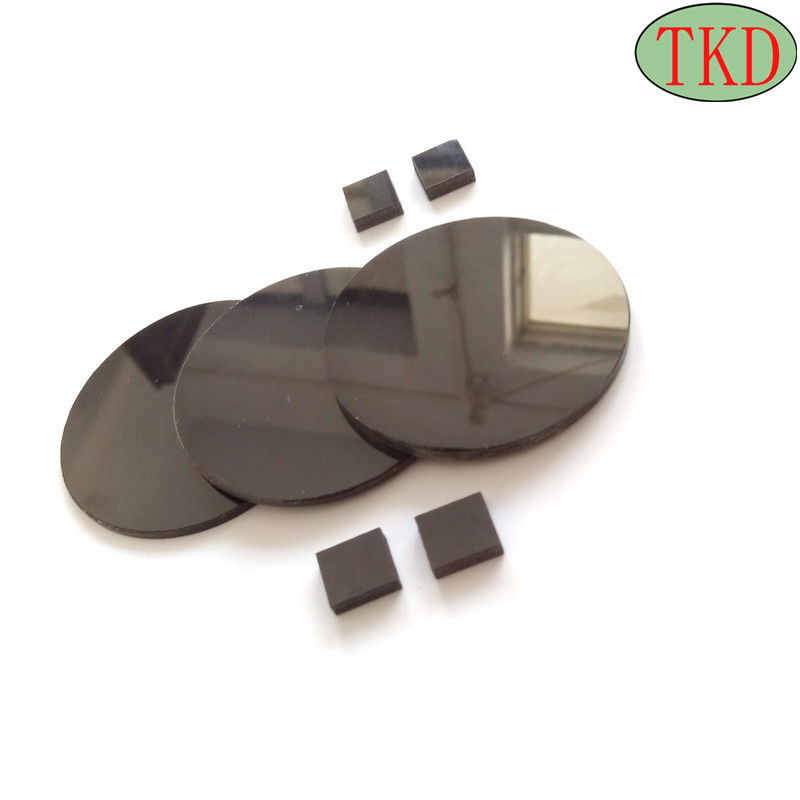

Polycrystalline diamond compact is composed of carbide substrate and polycrystalline diamond layer.

The diamond content of polycrystalline layers is more than 90%.

The item possesses high hardness, wear resistance and excellent impact resistance, which make it ideal super hard composite materials that achieve high efficient performance.

Diamond grains and introduction

| Product series | diamond grains(μm) | Diamond Volume % | Features | Applications |

| HPD-02 | 1-3 | 》92 | Excellent EDM processing,with normal life, better heat and impact resistance | Superfinishing, excellent surface processing quality for copper, bronze, aluminum, magnesium, plastic, precious metals etc |

| HPD-05 | 4-6 | 》92 | Excellent EDM processing, with normal life, better heat and impact resistance | Superfinishing, excellent surface processing quality for copper, bronze, aluminum, magnesium, magnesium aluminum alloy, plastic, plexiglass etc |

| HPD-10 | 8-12 | 》95 | Excellent EDM processing, with long life, better heat and impact resistance | Fine machining, very good surface processing quality, for aluminum alloy(Si content<12%) copper alloy, composite wood processing, high-precision wear-resistant corbelled device, etc |

| HPD-25 | 5-10, 20-30 | 》95 | Good EDM processing feature, long life, better heat and impact resistance | composite, laminate flooring, nonmetal hard and brittle materials, carbide alloy, graphite and graphite composites, aluminum silicon alloy (Si content>12%), ceramics, carbide etc. |

| HPD-302 | 1-3, 25-35 | 》95 | Good EDM processing feature, long life, better heat and impact resistance | composite, laminate flooring, nonmetal hard and brittle materials, carbide alloy, graphite and graphite composites, aluminum silicon alloy (Si content>12%), ceramics, carbide etc. |

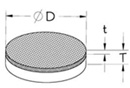

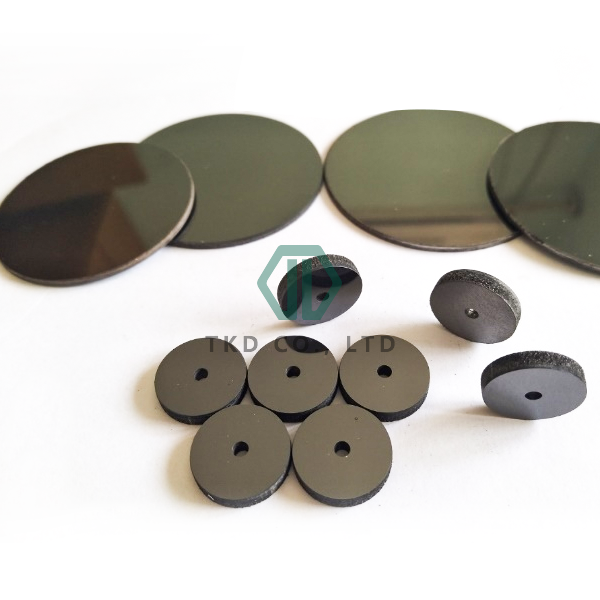

| PCD Diamond Compact Full-Round Blanks | |||||

| D/mm | Size (A x D) | T/mm | t/mm | Diamond grain size/μm |

| 76+/-0.1 (E6) | 360 R x76 | 1.6/2.0 | 0.45+/-0.1 | CMX850, CTB002,CTB010,CTH025,CTM302 | |

| 58 +/-0.1 | 360 R x58 | 1.6/2.0/3.2/4.5/8.0 | 0.50+/-0.1 1.00+/0.1 | 5 / 10 / 25 | |

| 55 +/-0.1 | 360 R x55 | 2 / 5 / 10 / 25 /302 | |||

| 51 +/-0.1 | 360 R x51 | 2 / 5 / 10 / 25 /302 | |||

| 48+/-0.1 | 360 R x48 | 1 / 5 / 10 / 25 /302 | |||

| 45+/-0.1 | 360 R x45 | 1 / 5 / 10 / 25 /302 | |||

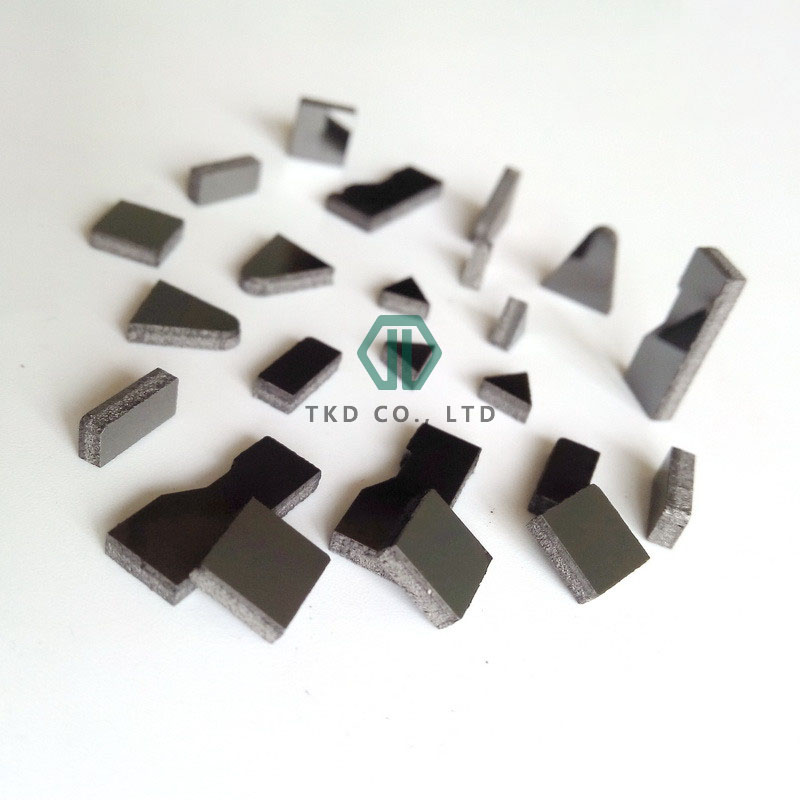

| Different shape of PCD cutting blanks / tips | |

| We offer straight cut, chamfering cut, hole drilling pcd blanks and tips as per client needs by laser cutting machine or EDM cutting machine. |

Working item: Copper, aluminum, non-ferrous metals and their alloys materials, wood, laminate flooring, graphite, rubber, plastic, ceramic and refractory materials, also as wear parts for inspection instruments etc.

Quality control of PCD blanks/discs:

Henan Precision Diamond values quality and consistency as top importance !

We guarantee every single pcs will be strictly inspected by ultrasonically scanned before delivery.

For the problem like unflatness, internal defects, tiny scratches, chips, poor tolerance and size etc, we all sort out and label them as rejection. The rejections are not allowed to be sold out !

Meanwhile, each batch of PCD will be taken by random for 10% to make the testing of abrasive ratio. Only the PCD discs are tested to meet our quality inspection standard, we will tag it as standard products for sales.

Whatsapp/wechat

Whatsapp/wechat