New Patented Item-silicon thermal solid PCD and TS-Pax.

Polycrystalline Diamond PCD die blank material is made by sintering diamond micropowder under the action of various catalysts using high temperature and high pressure processes. During the sintering process, a high degree of bonding is formed between the diamond particles, which strongly binds the diamond powder particles together to form polycrystalline diamond (PCD).Polycrystalline Diamond PCD die blank has high wear resistance, hardness and thermal conductivity,also has good mechanical strength and toughness.

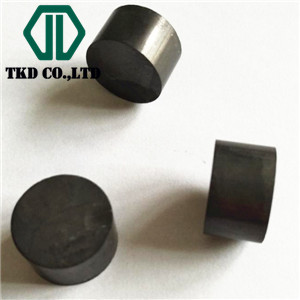

Our PCD blank material is a ceramic bonded diamond composite with wear resistance, high mechanical strength and high temperature performance. PCD die blanks are free standing cylinders, which are electrically conductive and can be easily pierced using EDM technology. These die blanks are thermally stable up to 1150°C.

Polycrystalline Diamond PCD die blank material is self-supported thermally stable blanks which are especially suited for applications required high temperature in mounting and need high heat resistance, such as in drawing for wire stranding,bunching and compactiong applications.It is suitable for drawing non-ferrous metals such as copper, aluminum, nickel, stainless steel and various alloys Wire.

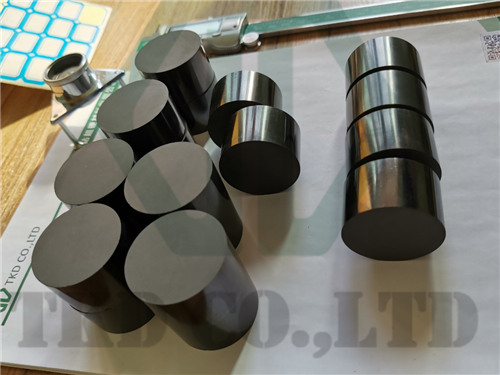

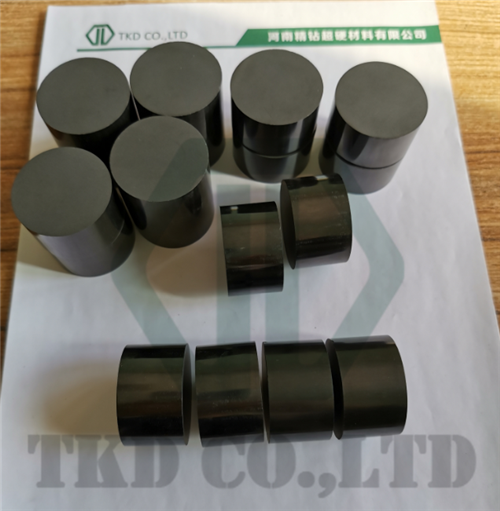

Self supported die blanks range in size from ADDMA standard D-6 all the way up to D-36. This provides a lower cost way to fabricate dies from smaller to larger wire sizes.

If you want diameters more than 36mm for other usage, we can also produce.

After EDM cutting, tolerance for height and diameter both tolerance at +/-0.01mm shown on pictures.

Feature:

1, Good electric conductivity to use EDM processing way for any shape and any size at precise size and tolerance(+/-0.01mm). Flatness, squareness of insert are all very nice.

2. High thermal stability at 1150°C;

3. High wear resistance,wear ratio >10×104;

4. Low coefficient of friction,good thermal conductivity,low thermal expansion coefficient.

5. Corrosion resistance (various acids, alkalis, salts), strong oxidation resistance, light weight.

Main application:

Special shaped wire drawing die and wear-resistant wear parts.

Whatsapp/wechat

Whatsapp/wechat