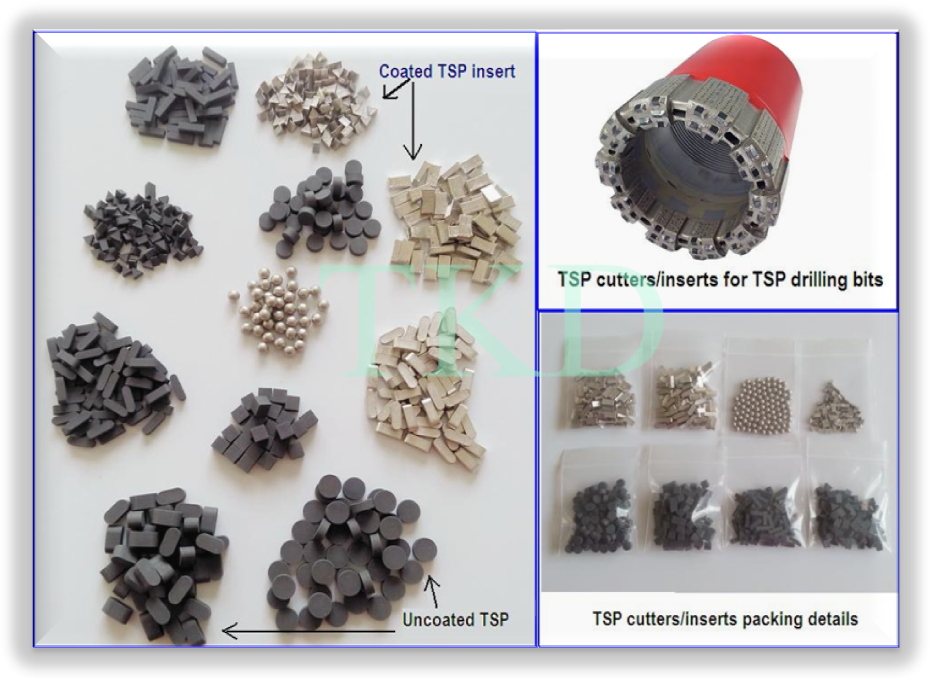

TKD latest type of silicon TSP solid and silicon TS-Pax inserts are the advanced, tougher and of higher precision market driven items.

Compared with conventional TSP insert

Our new generation types have 2-3 times higher wear resistance feature and superior electrical machinability and super large size at cylinder shape: φ40 × 22mm !

From raw materials strict control, scientific and reasonable proportioning design andstable parameter control,we guarantee to offer high standard and stable quality items.

At present, TKD can provide diamond micro-powder size from 10μm-40μm,the maximum size is φ40 × 22mm at cylinder shape, the minimum size is φ2 × 2mm special size and shape can also be customized according to customer requirements.

TSP silicon solid insert/cutter feature:

1. High thermal stability at 1150°C;

2. High wear resistance, wear ratio>8-10 ×10000;

3. Low coefficient of friction, good thermal conductivity,low thermal expansion coefficient.

4. Corrosion resistance (various acids, alkalis, salts), strong oxidation resistance, light weight.

Main application:

1. Wire drawing die: drawing ferrous metals, non-ferrous metals, making rods, tubes and wires.

2. High-temperature corrosion resistant wear parts: oil nozzles, water cutting and sandblasting nozzles, drill gauge, oil seals, bearings, robot joints and so on.

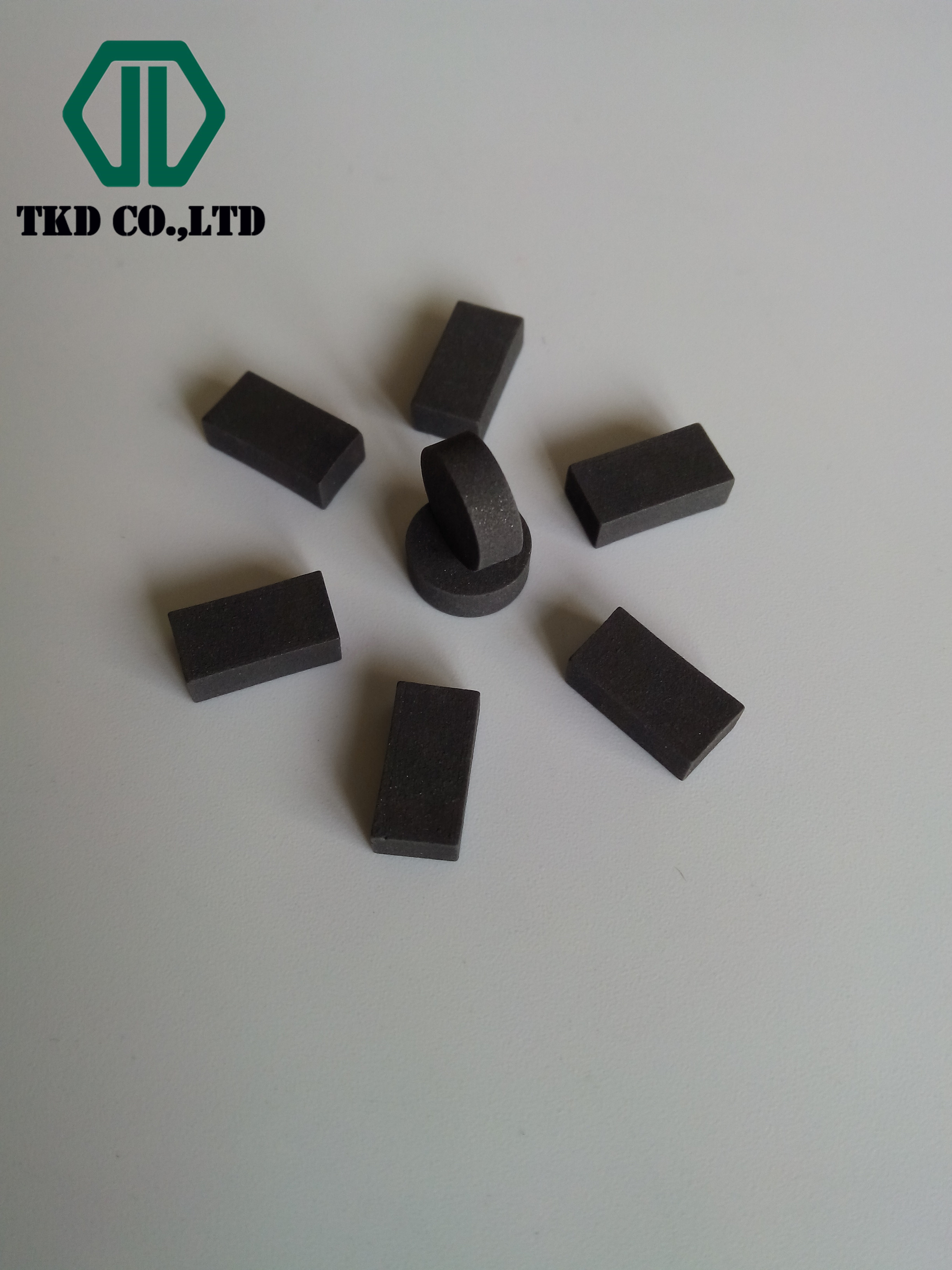

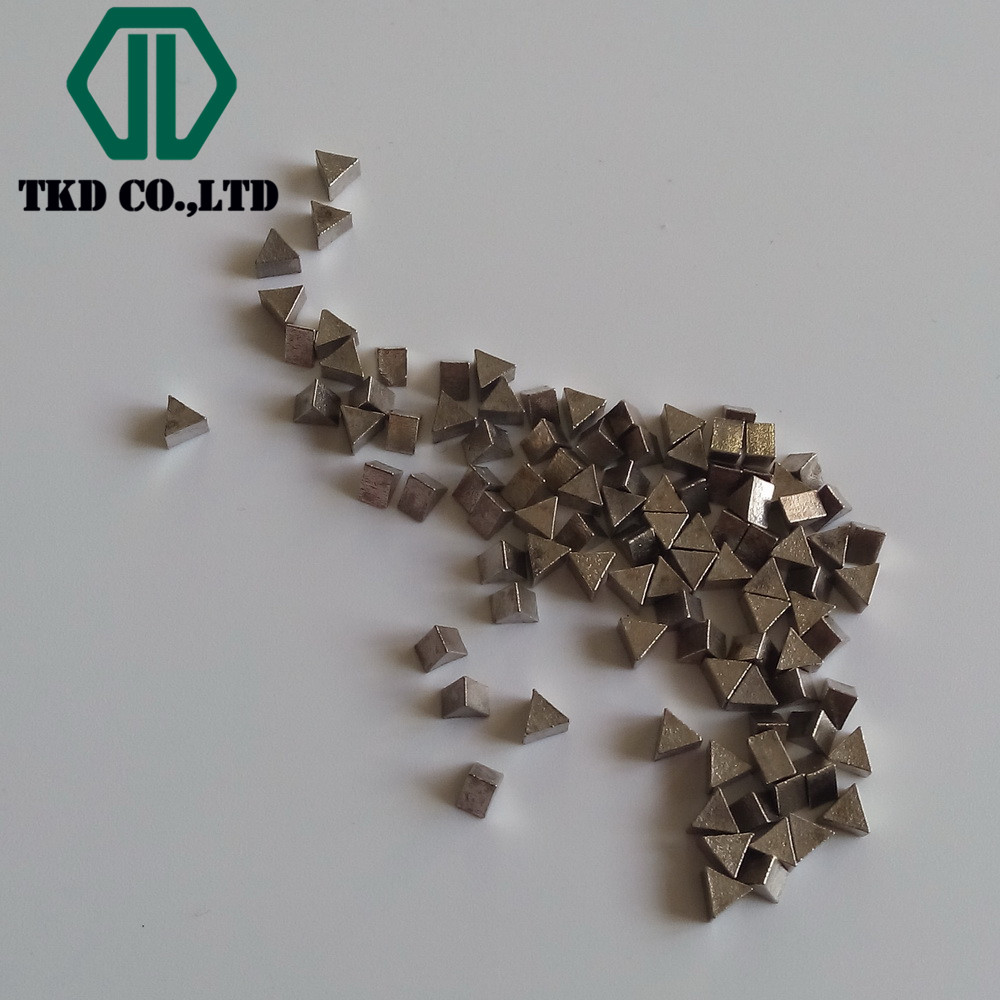

For gage cutter and cutting elements of drill bits, we supply thermal stable polycrystalline diamond(TSP) cutter specification below:

| Cylinder shape D x H x Angle (mm) | |||||

| 2x4x120° | 2x4x180° | 3x8 | 4x10 | 5x10 | 6.3x3.3 |

| 8x3 | 10x2 | 10x3 | |||

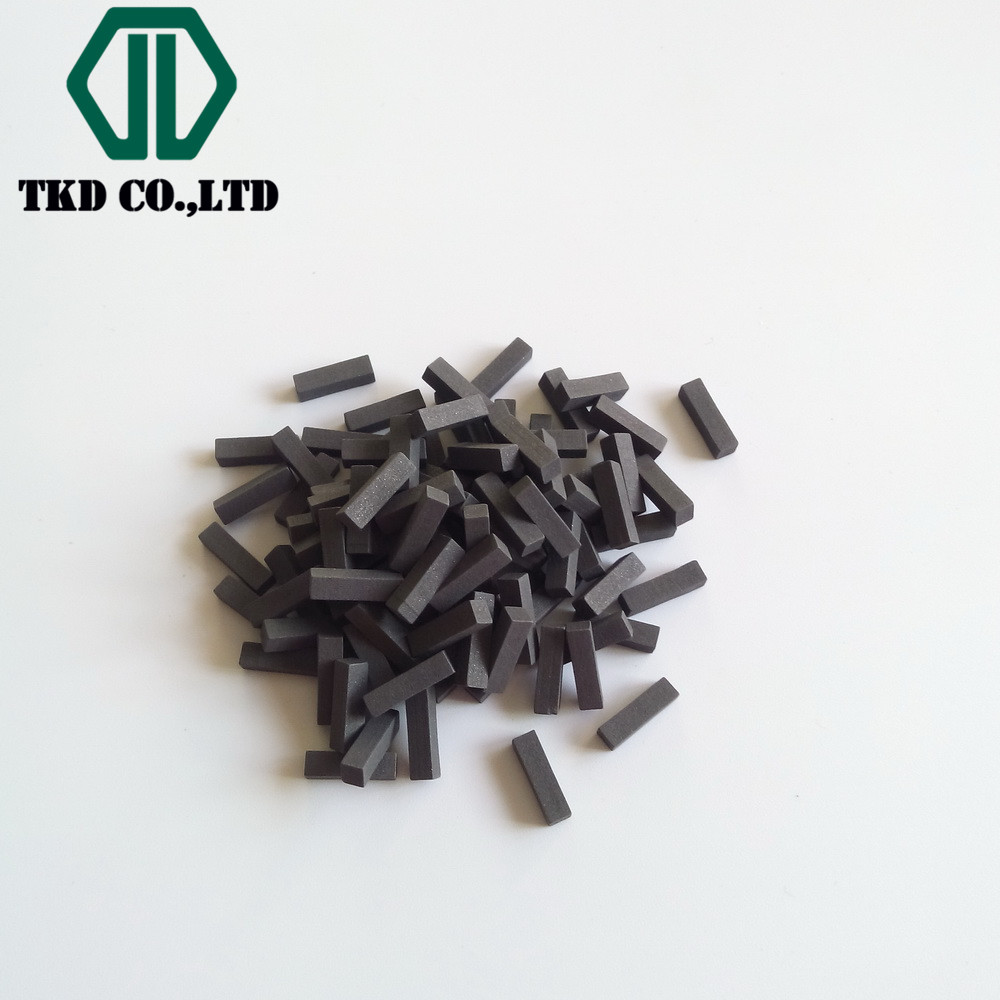

| Rectangle shape L x W x H(mm) | |||||

| 1.5x1.5x5 | 1.5x1.5x4 | 1.5x1.5x10 | 3x3x3 | 3x3x10 | 5x5x5 |

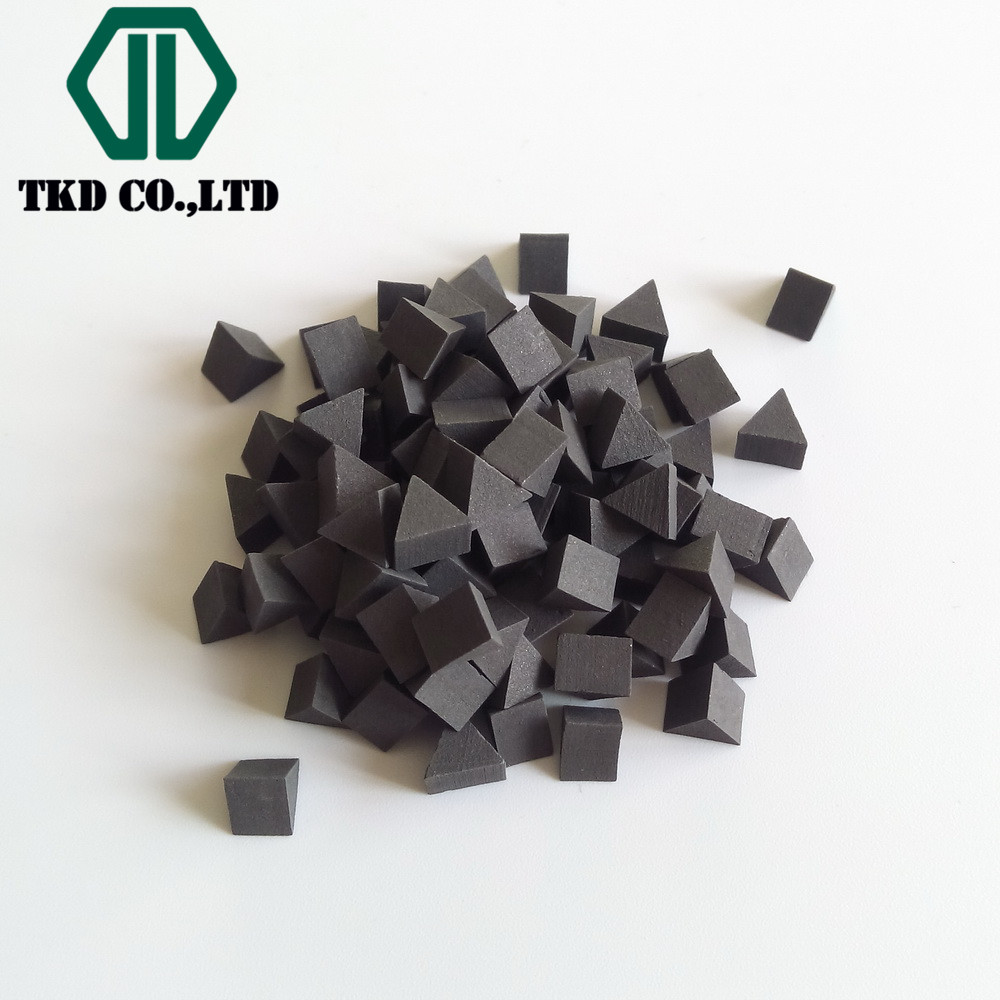

| Triangle shape (L1 x L2 x L3) | |||||

| 4x4x4x2.6 | 5x5x5x3 | 6x6x6x4.3 | |||

| Special shape W x H x Radius(mm) | |||||

| 3x3x10xR1.5 | 5x5x10xR3 | ||||

Advantage for wire drawing application:

In the processing of copper and aluminum, the die life is more than 100 times of cemented carbide;

the lifespan of steel wire and stainless steel wire is more than 50 times of cemented carbide, and the life of the die is prolonged. This ensures consistent wire size for the customer's finished product. High efficiency with precise stable size of wire and low cost are of big support.

Warm reminder: 1, support hot inserting at temperature 800 ~ 850 degrees, under the premise of the steel sleeve is not phase change may be appropriate to increase the jacket temperature

You may increase properly the temperature on condition that the steel sleeve not changed shape.

Whatsapp/wechat

Whatsapp/wechat